1. Introduction

1.1 Relevance of Propane Conversion

The Nissan K24 engine is widely respected for its performance and durability, making it a popular choice among automotive enthusiasts. As concerns about environmental impact and fuel costs grow, many are exploring alternative fuel options, including propane. Converting the Nissan K24 engine to run on propane offers several advantages, including reduced emissions, lower fuel costs, and extended engine life.

1.2 Overview of the Article

This article delves into the specifics of the Nissan K24 propane conversion process. We will cover everything from understanding the engine’s specifications to the benefits of propane, key components of the conversion system, and how to interpret the parts diagram. Additionally, we’ll provide insights from industry experts, safety considerations, and a comprehensive FAQ section to address common questions.

2. Understanding the Nissan K24 Engine

2.1 Engine Specifications

The Nissan K24 engine is a 2.4-liter inline-4 engine known for its reliability and efficiency. It is commonly found in various Nissan models and is prized for its balance of power and fuel economy. The engine’s robust design makes it an ideal candidate for propane conversion, allowing users to take advantage of alternative fuel options without sacrificing performance.

2.2 Common Applications

The K24 engine is used in a range of vehicles, including sedans, trucks, and SUVs. Its versatility makes it a favorite among drivers who require a reliable engine for daily commuting, heavy-duty tasks, or even racing applications. The propane conversion is particularly attractive for fleet vehicles, where cost savings and reduced environmental impact are prioritized.

3. Benefits of Propane Conversion

3.1 Environmental Impact

One of the most significant benefits of converting the Nissan K24 engine to propane is the reduction in harmful emissions. Propane is a cleaner-burning fuel compared to gasoline, producing fewer carbon dioxide, nitrogen oxides, and particulate matter. This makes it an environmentally friendly option for those looking to reduce their carbon footprint.

3.2 Economic Benefits

Propane is often less expensive than gasoline, offering significant cost savings over time. Additionally, propane engines typically require less frequent maintenance due to the cleaner combustion process, leading to lower long-term maintenance costs. For fleet operators, these savings can be substantial.

3.3 Performance Considerations

While propane has a lower energy density than gasoline, modern propane systems are designed to maximize efficiency, ensuring that performance remains comparable. Some users even report smoother engine operation and longer engine life due to the cleaner combustion properties of propane.

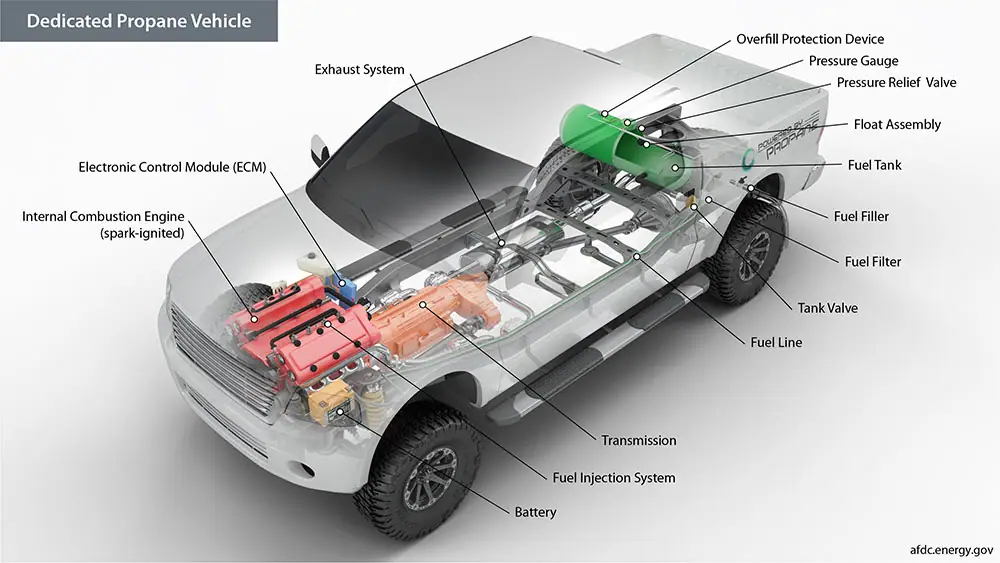

4. Key Components in a Propane System

4.1 Propane Fuel Tank

The propane fuel tank is the central storage unit for the propane gas. It is usually installed in the trunk or under the vehicle, depending on the available space and safety requirements. The tank is designed to hold propane in liquid form under high pressure and includes safety features like a pressure relief valve and a fill valve.

4.2 Propane Fuel Line

The fuel line connects the propane tank to the engine, allowing the gas to flow smoothly from storage to combustion. Made from high-pressure-resistant materials, the fuel line ensures that propane is delivered safely and efficiently to the engine.

4.3 Fuel Converter (Vaporizer)

The fuel converter, or vaporizer, is a critical component that converts liquid propane into a gaseous state, making it suitable for combustion. This process involves reducing the pressure of the propane and heating it using engine coolant. The vaporizer ensures that the fuel is properly prepared for injection into the engine.

4.4 Propane Carburetor or Injection System

Depending on the specific setup, the engine will use either a propane-specific carburetor or a fuel injection system. The carburetor mixes the propane vapor with air before it enters the combustion chamber, while a fuel injection system delivers precise amounts of fuel directly to the engine’s cylinders.

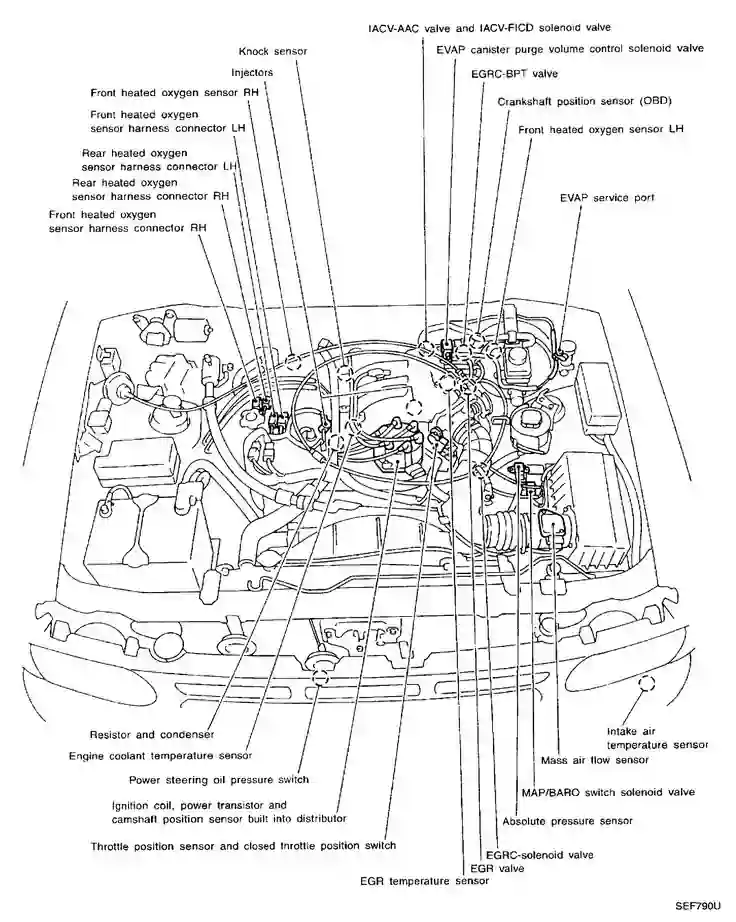

4.5 Electronic Control Unit (ECU)

The ECU manages the engine’s functions, including the air-fuel mixture, ignition timing, and other critical parameters. In a propane-powered engine, the ECU is programmed to optimize these functions for propane, ensuring efficient and reliable operation.

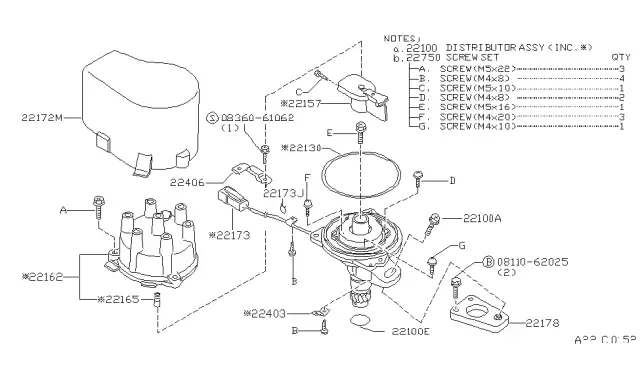

4.6 Ignition System

Propane engines require a more robust ignition system due to the different combustion properties of propane compared to gasoline. The ignition system includes spark plugs, ignition coils, and possibly a distributor, all of which are designed to ignite the propane-air mixture at the correct time for optimal performance.

4.7 Exhaust System

The exhaust system in a propane-powered engine may include components designed to handle the cleaner emissions produced by propane. This could involve a catalytic converter specifically tuned for propane, as well as oxygen sensors that help the ECU maintain the correct air-fuel ratio.

5. The Propane Parts Diagram

5.1 Overview of the Diagram

The propane parts diagram for the Nissan K24 engine provides a visual representation of how the various components are connected and interact with one another. This diagram is an essential tool for anyone involved in the conversion process, offering a clear overview of the system’s layout.

5.2 How to Interpret the Diagram

Interpreting the propane parts diagram involves understanding the flow of propane from the tank to the engine. The diagram will typically include labeled components, arrows indicating the direction of flow, and notes on key connections. It’s important to pay attention to safety features, such as pressure relief valves and the correct routing of fuel lines, to ensure a safe and efficient conversion.

6. Installation Process

6.1 Pre-Installation Checks

Before beginning the installation, it’s crucial to conduct a thorough inspection of the vehicle and components. This includes verifying the compatibility of the propane conversion kit with the Nissan K24 engine, checking for any existing issues with the engine or fuel system, and ensuring that all necessary tools and parts are on hand.

6.2 Step-by-Step Guide

The installation process typically involves several key steps, including mounting the propane tank, installing the fuel lines, connecting the vaporizer and carburetor or injection system, and programming the ECU for propane operation. Each step must be completed carefully to ensure a successful conversion.

6.3 Post-Installation Testing

After the installation is complete, a series of tests should be conducted to verify that the system is functioning correctly. This includes checking for leaks, verifying that the engine starts and runs smoothly on propane, and ensuring that all safety features are operational.

7. Safety Considerations

7.1 Handling Propane Safely

Propane is a highly flammable gas, so safety must be a top priority during the conversion process. This includes proper storage of the propane tank, secure installation of fuel lines, and regular inspection of the system for leaks or damage.

7.2 Maintenance Tips

Regular maintenance is essential for ensuring the longevity and safety of a propane-powered engine. This includes routine checks of the fuel system, cleaning or replacing filters, and ensuring that the ignition system is in good condition.

7.3 Regulatory Compliance

Converting a vehicle to run on propane may be subject to specific regulations, depending on the region. It’s important to be aware of any legal requirements, such as emissions standards or safety inspections, to ensure that the vehicle remains compliant.

8. Expert Insights

8.1 Industry Opinions

Experts in the automotive and alternative fuel industries generally view propane as a viable option for those looking to reduce fuel costs and environmental impact. Industry professionals often highlight the importance of proper installation and maintenance to ensure the safety and efficiency of propane-powered vehicles.

8.2 Case Studies

Several case studies have shown the successful conversion of Nissan K24 engines to propane, with positive results in terms of performance and cost savings. These examples provide valuable insights into the real-world application of propane conversion technology.

9. Future Outlook

9.1 Emerging Technologies in Propane Systems

As technology advances, new developments in propane conversion systems are making them more efficient and easier to install. Innovations such as advanced fuel injection systems and improved ECU programming are helping to maximize the benefits of propane as a fuel source.

9.2 Potential for Widespread Adoption

With the growing emphasis on sustainability and cost efficiency, the use of propane in automotive applications is likely to increase. As more drivers become aware of the benefits, propane could become a more common fuel choice, particularly for fleet vehicles and long-distance transportation.

10. Conclusion

10.1 Recap of Key Points

Converting a Nissan K24 engine to run on propane offers numerous benefits, including lower emissions, cost savings, and potential improvements in engine longevity. Understanding the key components and how they fit together is essential for a successful conversion.

10.2 Final Thoughts

While propane conversion requires an initial investment in terms of time and money, the long-term benefits make it a worthwhile consideration for those looking to reduce their environmental impact and fuel costs. With proper installation and maintenance, a propane-powered Nissan K24 engine can provide reliable and efficient performance.

11. FAQ

11.1 Common Questions about Propane Conversion

Q: Why should I convert my Nissan K24 engine to propane?

A: Converting to propane can reduce your fuel costs, lower your vehicle’s emissions, and extend the life of your engine due to cleaner combustion.

Q: How long does the conversion process take?

A: The conversion process typically takes several hours to a full day, depending on the complexity of the installation and the experience of the person performing it.

11.2 Technical Queries

Q: Will propane affect the performance of my K24 engine?

A: Propane may offer slightly different performance characteristics compared to gasoline, but most users find the difference negligible, with some even reporting smoother operation.

Q: Can I switch back to gasoline after converting to propane?

A: Yes, dual-fuel systems are available that allow you to switch between propane and gasoline, offering flexibility depending on your fuel availability and needs.

11.3 Safety Concerns

Q: Is propane safe to use in my vehicle?

A: When installed and maintained properly, propane is a safe and reliable fuel for automotive use. It is commonly used in a variety of vehicles, including fleet and commercial vehicles.

Q: What should I do if I smell propane in my vehicle?

A: If you detect a propane odour, turn off the engine immediately, exit the vehicle, and contact a professional to inspect the system for leaks.